Perfluorinated Polyether Oil (PFPE Oil)

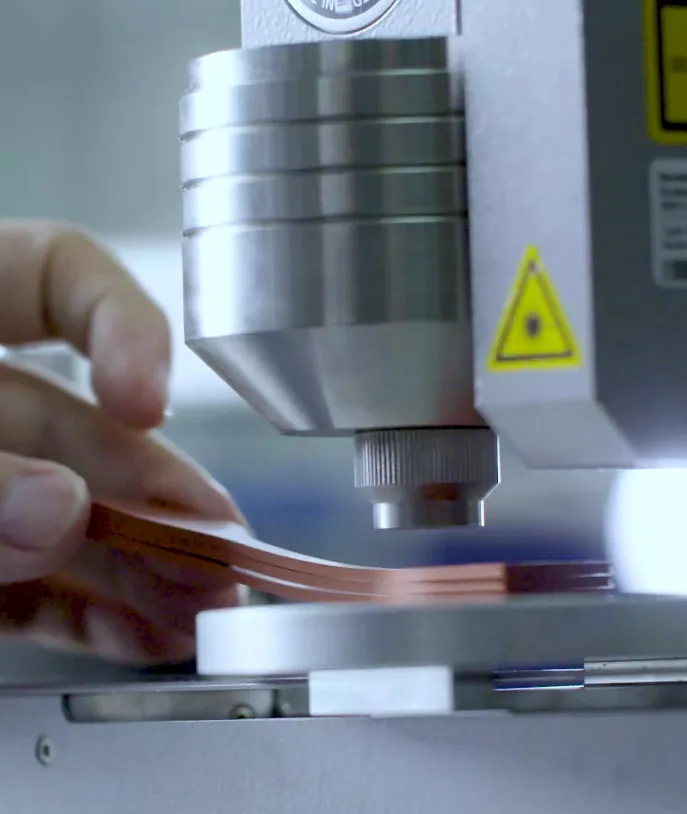

Perfluorinated polyether oil, also known as PFPE oil, is a high-performance synthetic lubricant designed for applications where chemical resistance, thermal stability, and long-lasting lubrication are essential. Its fluorinated molecular structure, composed of carbon, fluorine, and oxygen, allows it to withstand strong acids, bases, and corrosive substances without degrading, ensuring consistent performance in extreme environments. With a wide operating temperature range, PFPE oil remains thermally stable at high temperatures, preventing decomposition, while its low-temperature fluidity ensures smooth operation in extreme cold. Its low volatility and excellent lubricating properties help reduce friction and wear, extending the lifespan of mechanical components. PFPE oil is also compatible with a wide range of materials, making it suitable for electronics, aerospace, and chemical processing industries. It plays a critical role in the lubrication of hard disk drives, aircraft engines, and chemical processing equipment, providing reliable performance under demanding operating conditions.