- Home

- Applications

- Automotive

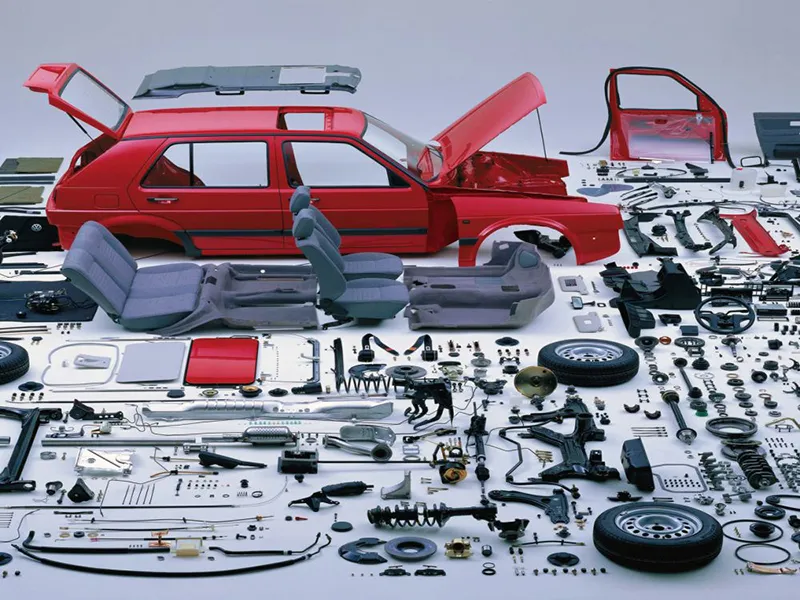

Automotive

Automotive applications require durable sealing materials that can withstand high temperatures, continuous fuel exposure, and mechanical stress. Fluoroelastomers provide long-term reliability in various critical automotive components, ensuring efficiency and safety in demanding conditions. The complexity of modern vehicles demands specialized sealing solutions for key systems. Fluoroelastomer compounds are widely used in the engine, fuel, and cooling systems, providing resistance to extreme conditions and ensuring long-term performance in the following applications:

Material Requirements

Material Requirements

Material Requirements

Material Requirements

Material Requirements

Material Requirements

Material Requirements

Material Requirements

Material Requirements

Material Requirements

Material Requirements

Material Requirements

We provide specialty rubber solutions for a wide range of industries, including automotive, semiconductor manufacturing, oil and gas, aerospace, and wearable technology. Each sector presents unique challenges, from high-temperature resistance and chemical exposure to precision sealing and mechanical durability.

Explore All Applications