Industry Background

Beyond FKM Materials—What Else Can Be Used Under PFAS Regulations?

In the smart wearable industry, fluoroelastomer (FKM) has long been the go-to material for high-end watch rubber strap due to its excellent resistance to oils, water, and high temperatures. But in recent years, with the tightening of global regulations on per- and polyfluoroalkyl substances (PFAS), manufacturers are now seeking safe yet diverse material options.

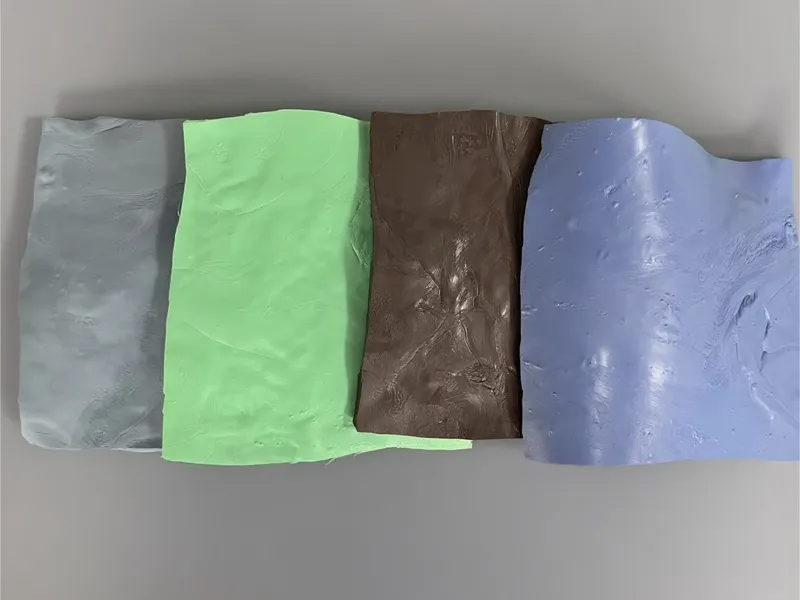

To widen the eco-friendly material options for manufacturer, we offer polyurethane (PU) rubber sheet materials with customizable colors, which have excellent flexibility, durability, and high resistance to water and oil. Additionally, PU rubber is an eco-friendly free-PFAS material. Hence, it has become a new choice in the smart wearable industry, offering more possibilities that comply with the environmental standards.

Our Solution: Improved Polyurethane (PU)

Polyurethane (PU) rubber is a widely recognized material in the smart wearable industry, valued for its outstanding flexibility, broad application range, and ease of processing.

However, despite its popularity, conventional PU rubber exhibits poor resistance to water and oleic substances such as skin oils and skincare products. This vulnerability arises from its intrinsic molecular structure, which contains lipophilic components—namely, the soft segments (e.g., polyether/polyester polyols) and hard segments (e.g., isocyanates)—that readily interact with oils, leading to swelling and gradual material degradation over time. For manufacturers, this often means making trade-offs between flexibility and long-term durability.

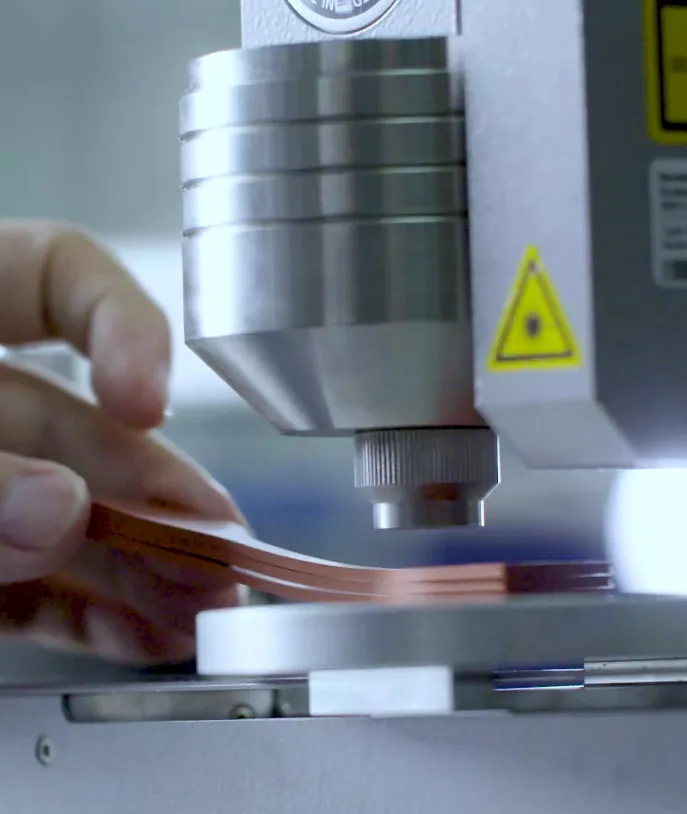

To solve this problem, our R&D team spent two years developing an advanced solution: a hydrolysis-resistant polyurethane, engineered at the molecular level to overcome these limitations.

This enhanced PU compound is synthesized using carefully selected hydrophobic monomers and incorporates a dense protective structure formed by reactive end-capping agents and cross-linking components. Unlike conventional approaches that rely on external surface coatings—which tend to wear off over time—our innovation ensures that the polyurethane is inherently resistant to both water and oil, while maintaining its excellent flexibility and processability.

Test Result

Our polyurethane rubber has passed the simulation usage tests to replicate real-life conditions, such as seawater immersion, high-humidity and heat exposure (85°C/85%RH), oleic acid exposure, etc. The result below showed that our new PU rubber sheet has high water and oil resistance:

| Polyurethane(PU) | Initial Retention Force (N) | Double 85 test (N) (85°℃@85%RH/7d) | Tensile Testing under Varying Environmental Conditions |

| Oleic acid (N) (50°C/16h) | Sweat (N) (25°C/48h) | Swimming pool (N) (25°C/48h) | Seawater (N) (23°C/24h) | Contact with water (/°) |

| Si-TPU | >100 | >100 | >100 | >100 | >100 | >100 | >100 |

| Si-MPU | >100 | >100 | >100 | >100 | >100 | >100 | >100 |

Strength retention rate exceeds 95% after Double 85 testing.

Strength retention rate exceeds 95% after seawater and saltwater exposure tests.