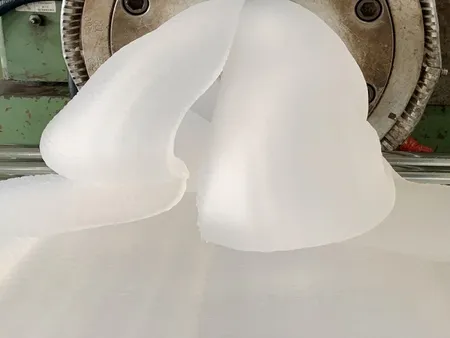

FKM Raw Gum Properties

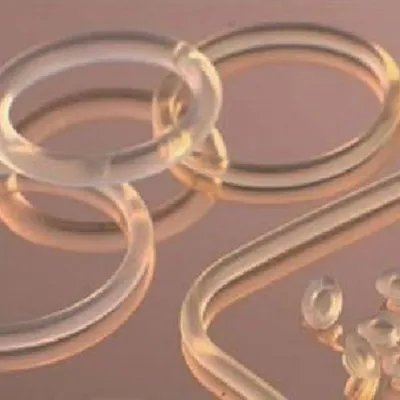

Fluoroelastomer raw gum is designed for applications that demand durability, chemical stability, and resistance to extreme temperatures. Its unique polymer structure allows it to maintain performance under mechanical stress and harsh environmental conditions. To better understand its capabilities, here are the key properties that make FKM raw gum a preferred material in various industries:

- Mechanical Performance

FKM raw gum offers high tensile strength and abrasion resistance, ensuring that it maintains its structure even under continuous stress. It has a Shore A hardness of 65–85, with a tensile strength of 8–18 MPa and an elongation at break of 150%–300%, making it suitable for applications that require flexibility and long-term mechanical integrity.

- Chemical and Oil Resistance

FKM raw gum is highly resistant to acids, bases, and organic solvents, allowing it to perform reliably in chemically aggressive environments. Its oil resistance makes it a preferred choice for applications where prolonged exposure to lubricants, fuels, and hydraulic fluids is expected. Additionally, it offers good weathering resistance, preventing degradation from long-term atmospheric exposure.

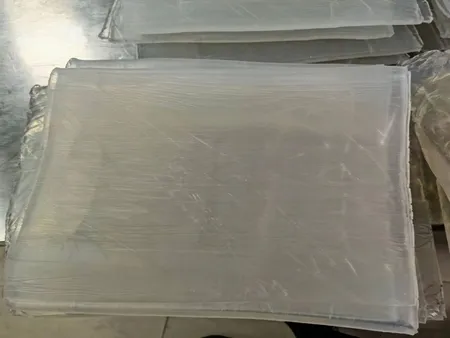

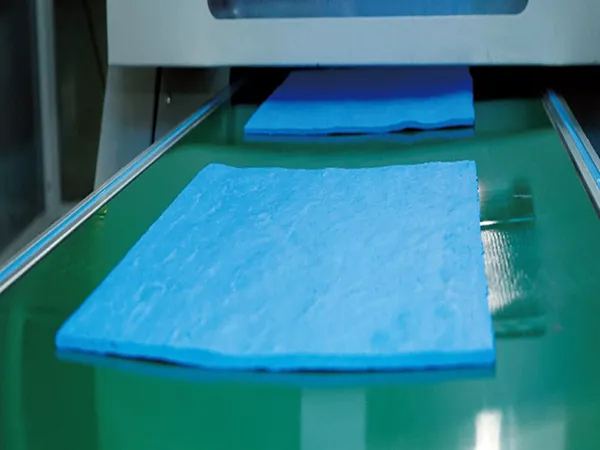

- Physical Properties

FKM raw gum has a relatively high density, giving it a more solid and stable structure. It is typically available as a white or slightly yellow solid, with a firm yet flexible consistency that allows for efficient processing and shaping into various industrial components.

- Thermal Performance

Designed for high-temperature applications, FKM raw gum retains its physical and chemical stability above 200°C, making it suitable for extreme heat environments. At the same time, it maintains good low-temperature flexibility, preventing brittleness in colder conditions.