Rubber Compounds

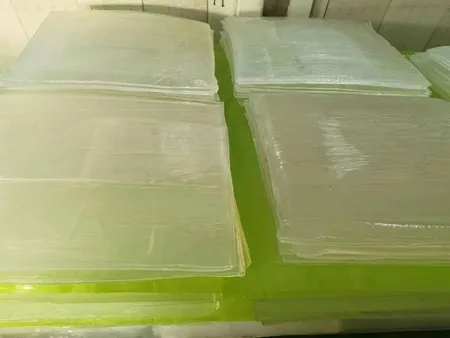

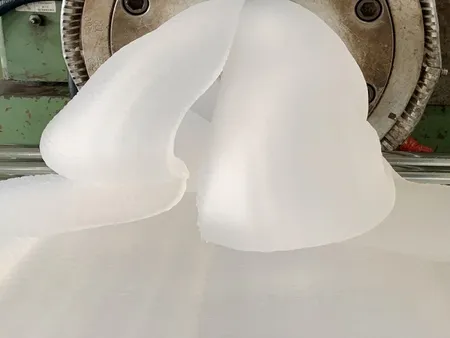

Fluoroelastomer Compound

Fluoroelastomer compound is formulated to provide reliable chemical and heat resistance, making it suitable for demanding industrial applications. Built on an FKM raw gum base, it benefits from the high fluorine content and stable carbon-fluorine bonds that give fluoroelastomers their durability.

To enhance processing and performance, various curing agents, accelerators, and fillers are incorporated during compounding. This allows for greater flexibility in formulation, enabling manufacturers to tailor rubber compounds for sealing, insulation, and protective applications across industries that require consistent performance in extreme conditions.