| Product Code |

Nominal Viscosity ML (1+10) |

Specific Gravity (g/cm³) |

Fluorine Content (%) |

Tensile (MPa) |

Elongation (%) |

Hardness Shore A |

Compression Set (%) 70h@200℃ |

TR10 (℃) |

Volume Change (Fuel C) |

Typical Applications |

| F Series: Bisphenol Copolymer series. Miscellaneous applications with balanced performance and processing properties |

| F201A |

25 |

1.83 |

66 |

13 |

220 |

78 |

16 |

-17 |

4.0% |

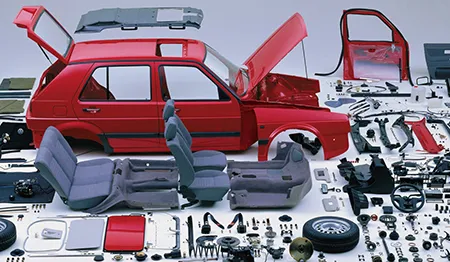

O-rings, gaskets, injection molding components |

| F301A |

30 |

1.83 |

66 |

14 |

220 |

77 |

17 |

-17 |

3.9% |

O-rings, gaskets, and some sealing parts that required low compression set |

| F401A |

40 |

1.83 |

66 |

15 |

210 |

76 |

15 |

-17 |

3.8% |

O-rings, gaskets, and some FDA-standard sealing components |

| F501A |

50 |

1.83 |

66 |

15.3 |

230 |

76 |

16 |

-17 |

3.8% |

O-rings, gaskets, and sealing components |

| F601A |

60 |

1.83 |

66 |

16.2 |

220 |

77 |

13 |

-17 |

3.5% |

O-rings, gaskets, and some sealing components that required low compression set |

| F901A |

90 |

1.83 |

66 |

17.8 |

240 |

77 |

11 |

-17 |

3.5% |

O-rings, gaskets, and compression molding components |

| F375B |

32 |

1.82 |

66 |

14.5 |

250 |

77 |

20 |

-17 |

3.7% |

Valve stem oil seals, shaft seals, and parts with complicated geometries |

| F475B |

40 |

1.83 |

66 |

15 |

230 |

75 |

19 |

-17 |

4.0% |

Valve stem oil seals, shaft seals, and parts with complicated geometries |

| F561B |

55 |

1.83 |

66 |

15.7 |

260 |

78 |

21 |

-17 |

4.0% |

Oil seals, oil shaft seals, and some parts require a bonding property |

| F445C |

40 |

1.83 |

66 |

14.3 |

250 |

75 |

18 |

-17 |

4.0% |

Rubber parts with complicated shapes, like valves and bellows |

| F201E |

22 |

1.84 |

66 |

13 |

250 |

75 |

25 |

-17 |

4.0% |

Hose and other extrusion parts |

| T and HT TL Series: Bisphenol Terpolymer series. Enhance resistance to heat & chemicals, combined with high resistance to compression set. |

| T401A |

40 |

1.85 |

68 |

14.5 |

240 |

78 |

28 |

-13 |

3.0% |

General purpose, O-rings, gaskets, and moulded parts |

| T601A |

60 |

1.85 |

68 |

15.4 |

230 |

79 |

24 |

-13 |

3.0% |

General purpose, O-rings, gaskets, moulded parts |

| T301B |

35 |

1.86 |

68 |

13.5 |

250 |

77 |

35 |

-13 |

3.0% |

General purpose, oil seals, shaft seals, valve seals, and parts that require bonding or adhesion |

| T401B |

40 |

1.86 |

68 |

14.6 |

260 |

77 |

35 |

-12 |

2.0% |

General purpose, oil seals, shaft seals, valve seals, and parts that require bonding or adhesion |

| T401C |

46 |

1.86 |

68 |

14.2 |

270 |

77 |

26 |

-12 |

2.0% |

General purpose, O-rings and gaskets, moulded parts |

| T 201E |

27 |

1.86 |

69 |

13.1 |

300 |

76 |

35 |

-12 |

2.0% |

Fuel hose that required bonding with ECO, like an extruded hose |

| HT 501C |

50 |

1.89 |

70 |

14.8 |

250 |

79 |

39 |

-9 |

1.2% |

Rubber parts with complicated shapes |

| HT 601A |

55 |

1.89 |

70 |

15.5 |

240 |

79 |

37 |

-9 |

1.2% |

Sealing components that required low fuel permeability |

| TL 301A |

30 |

1.8 |

66 |

14 |

230 |

78 |

26 |

-19 |

4.0% |

General purpose, O-rings, gaskets, and extruded profiles |

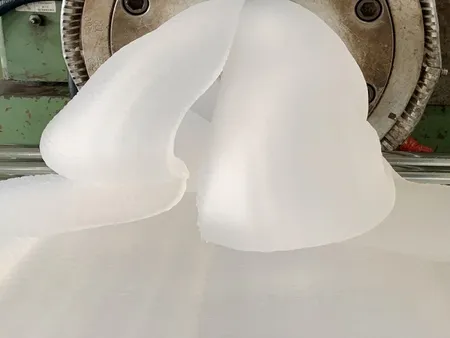

F375B Medium Mooney Bisphenol Copolymer Precompound, Hardness 77

F375B Medium Mooney Bisphenol Copolymer Precompound, Hardness 77 HT401A Medium Mooney Bisphenol Terpolymer Precompound, Hardness 78

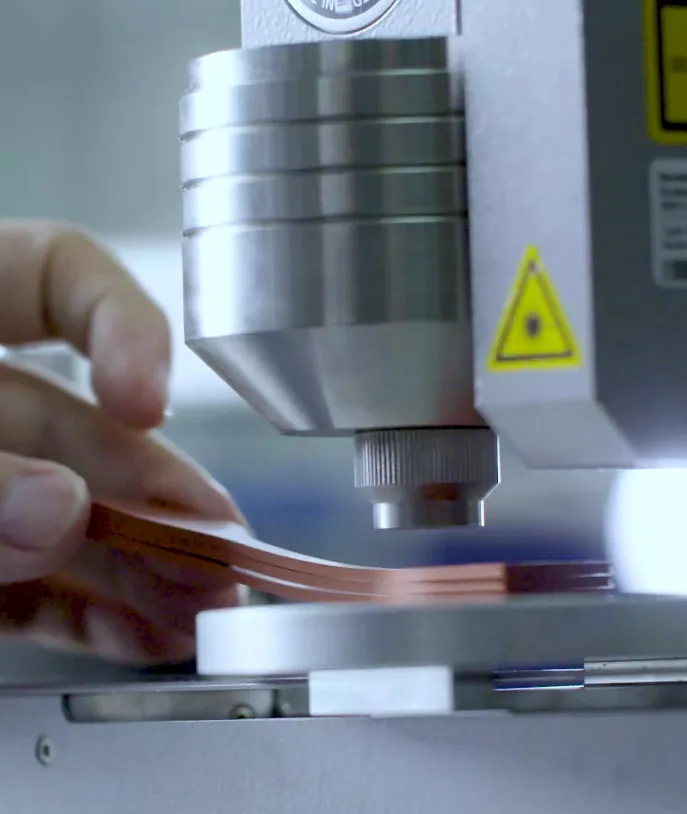

HT401A Medium Mooney Bisphenol Terpolymer Precompound, Hardness 78 T405A Medium Mooney Bisphenol Terpolymer Precompound, Hardness 76

T405A Medium Mooney Bisphenol Terpolymer Precompound, Hardness 76