Rubber Compounds

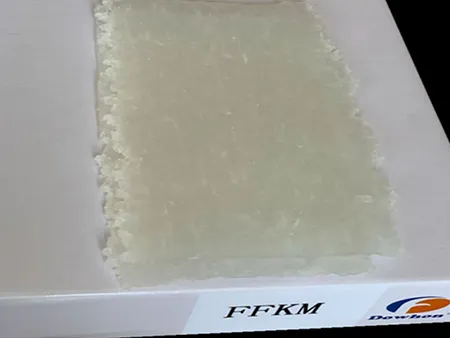

Perfluoroelastomer Raw Gum

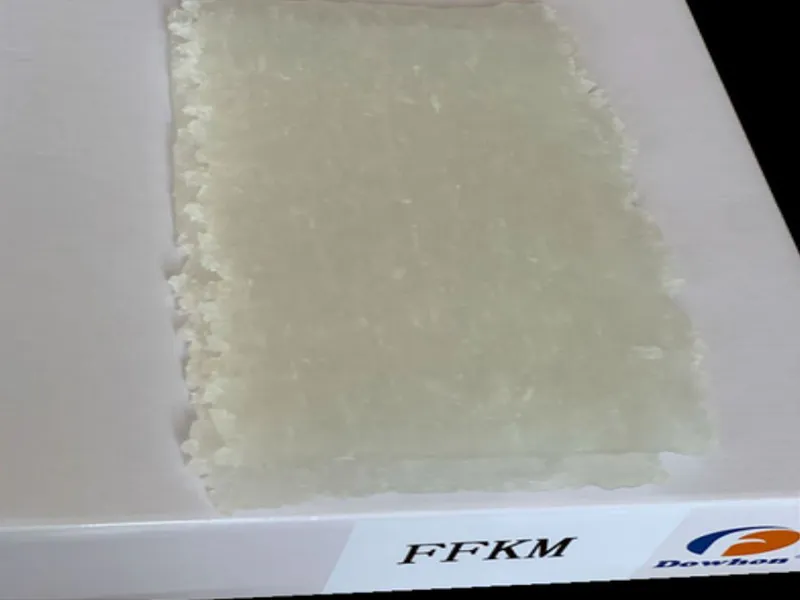

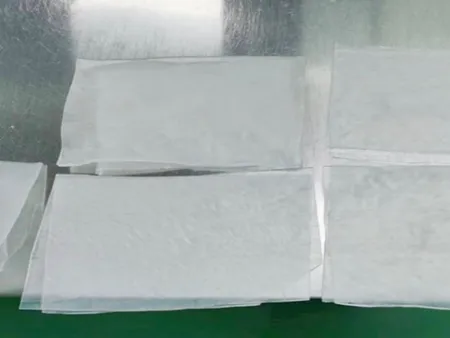

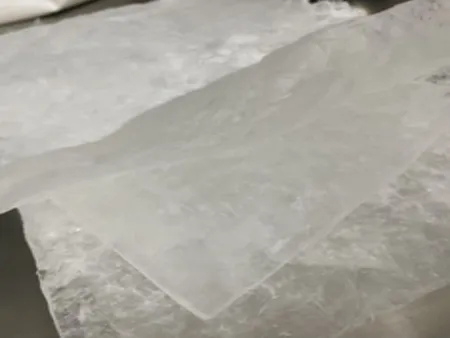

Perfluoroelastomer raw gum is a specialized elastomer designed for industries that demand exceptional durability in harsh environments. Made from fluorinated monomers, its molecular structure includes fluorine atoms and ether bonds, which enhance its resistance to aggressive chemicals like strong acids, bases, and organic solvents. It performs reliably across a broad temperature range, from -10℃ to over 315℃, maintaining stability even in extreme conditions. With low gas permeability and minimal moisture absorption, it supports effective sealing in critical applications. Available in white or light yellow solid blocks or sheets, FFKM raw gum provides elasticity while retaining structural integrity. This rubber compound is widely used in manufacturing high-performance seals and components for industries such as chemical processing, aerospace, and electronics, where reliability and longevity are key.