Rubber Compounds

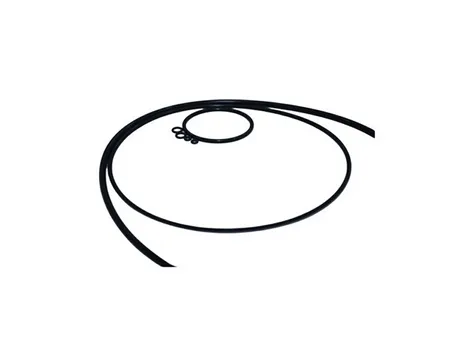

Perfluoroelastomer O-Ring (FFKM O-Ring)

Specialty rubber compounding solutions in chemically aggressive and high-temperature environments demand materials that can handle prolonged exposure without degradation. FFKM O-rings are engineered for exactly that, offering outstanding chemical resistance where standard fluoroelastomers fall short. Unlike conventional elastomers, which break down when exposed to ethers, amines, ketones, oxidizers, fuels, acids, and bases, FFKM retains its sealing integrity and mechanical stability, ensuring long-term performance in critical applications.

Withstanding exposure to over 1,600 different chemicals, FFKM O-rings are widely used in chemical processing, aerospace, and semiconductor industries, where material failure is not an option. Even after six months of immersion in a solution of toluene, acetone, and dichloromethane, FFKM exhibits minimal volume change, while other elastomers experience significant deformation. This level of chemical and thermal durability makes them a trusted choice for sealing applications that require long-term reliability.